Metal Recycling: A Comprehensive Guide

What is Metal Recycling?

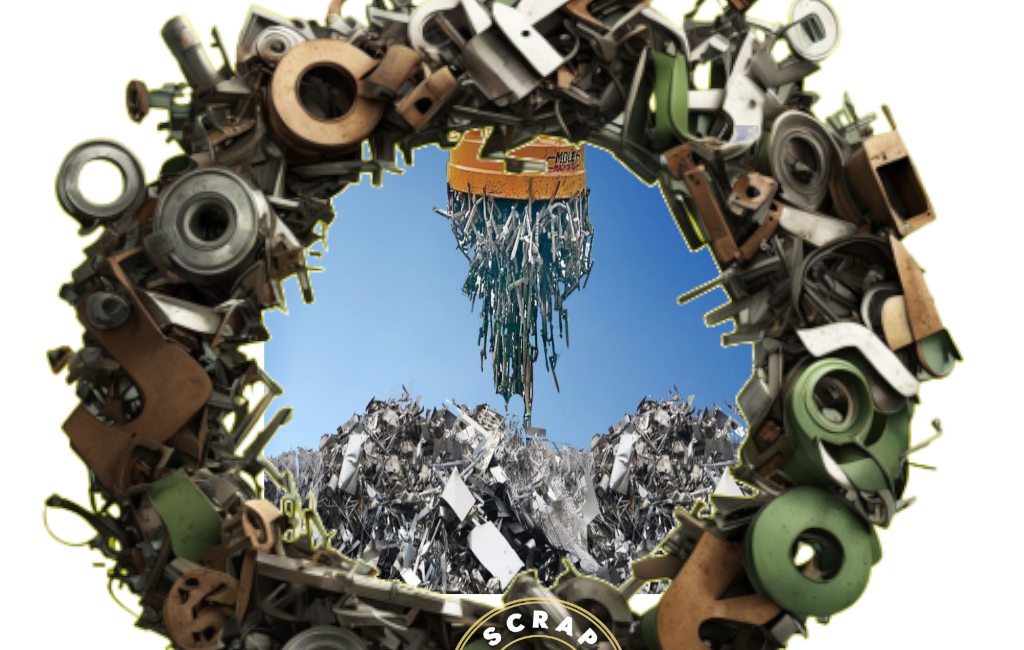

Metal recycling involves collecting, processing, and reusing scrap metal to produce new products. The process not only reduces the need for mining raw materials but also decreases energy use and greenhouse gas emissions. Metals commonly recycled include aluminum, steel, copper, brass, and precious metals like gold and silver.

Types of Metals:

- Ferrous Metals:

- Contain iron, such as steel and cast iron.

- Magnetic and often used in construction and manufacturing.

- Non-Ferrous Metals:

- Do not contain iron, such as aluminum, copper, and zinc.

- Lighter and more resistant to corrosion, making them suitable for various applications.

The Importance of Metal Recycling

Environmental Benefits:

- Conservation of Natural Resources:

- Recycling reduces the need for mining, preserving finite resources like iron ore, bauxite, and copper.

- Energy Efficiency:

- Recycling metals requires significantly less energy than producing them from raw materials. For instance, recycling aluminum saves up to 95% of the energy needed for primary production.

- Reduction in Greenhouse Gases:

- Lower energy use translates to fewer carbon emissions, helping combat climate change.

Economic Benefits:

- Cost Savings:

- Recycling is more economical than mining and processing raw materials.

- Job Creation:

- The recycling industry provides employment in collection, sorting, and processing activities.

The Metal Recycling Process

The recycling of metals follows a systematic process that ensures efficiency and quality:

A. Collection:

- Scrap metals are collected from various sources, including industrial waste, household items, and construction debris.

- Common collection points include recycling centers, junkyards, and curbside recycling programs.

B. Sorting:

- Metals are sorted by type (ferrous vs. non-ferrous) and quality using magnets, sensors, or manual inspection.

C. Cleaning and Preparation:

- Contaminants like paint, plastic, and dirt are removed to ensure purity.

- Metals may be shredded or compacted for easier handling and melting.

D. Melting:

- The prepared metals are melted in furnaces at high temperatures, tailored to each metal’s specific melting point.

E. Purification:

- Advanced techniques, such as electrolysis or chemical baths, are used to remove impurities and ensure high-quality recycled metal.

F. Solidification and Molding:

- The purified metal is poured into molds or processed into sheets, rods, or other shapes for reuse.

G. Distribution:

- The recycled metal is distributed to manufacturers for use in producing new products.

Challenges in Metal Recycling

Despite its advantages, metal recycling faces several hurdles:

A. Contamination:

- Mixing metals or introducing non-metal materials can lower the quality and recyclability of metals.

B. Infrastructure Gaps:

- Inadequate recycling facilities and collection systems can limit recycling rates.

C. Economic Viability:

- Fluctuations in metal prices can impact the profitability of recycling operations.

D. Public Awareness:

- Many people are unaware of what metals can be recycled or how to do so effectively.

Innovative Uses of Recycled Metals

Recycled metals find applications in various industries, including:

- Construction:

- Steel and aluminum from recycled sources are used in buildings, bridges, and infrastructure.

- Automotive:

- Recycled metals are integral to manufacturing car bodies, engines, and parts.

- Packaging:

- Aluminum cans and steel containers are made predominantly from recycled material.

- Electronics:

- Precious metals like gold, silver, and copper are recovered from e-waste for reuse in electronics.

Best Practices for Effective Metal Recycling

A. Promoting Public Participation:

- Educate communities about the benefits and methods of metal recycling.

B. Improving Collection Systems:

- Establish accessible recycling points and incentivize participation.

C. Investing in Technology:

- Advanced sorting and purification technologies can enhance efficiency.

D. Policy Support:

- Governments should implement regulations and incentives to encourage recycling.

Case Studies in Metal Recycling

A. Japan:

- Known for its high recycling rates, Japan has a well-established system for collecting and processing metals.

B. Germany:

- With strict waste management laws, Germany efficiently recycles both ferrous and non-ferrous metals.

C. United States:

- Initiatives like the “Metal Recycling Coalition” aim to boost recycling rates and innovation in the sector.

Future of Metal Recycling

The future of metal recycling looks promising with the integration of:

- Artificial Intelligence:

- AI-driven systems for sorting and processing metals.

- Blockchain Technology:

- Ensuring traceability and transparency in recycled metal supply chains.

- Circular Economy Models:

- Encouraging industries to design products with recyclability in mind.

- Global Collaboration:

- Sharing best practices and technologies across borders to improve recycling rates worldwide.

Conclusion

Metal recycling is a vital practice that supports environmental sustainability, economic growth, and resource conservation. By understanding the process, addressing challenges, and adopting innovative practices, we can unlock the full potential of metal recycling. As industries, governments, and individuals collaborate, the vision of a circular economy becomes increasingly achievable, ensuring a greener and more sustainable future for generations to come.

Leave a Comment